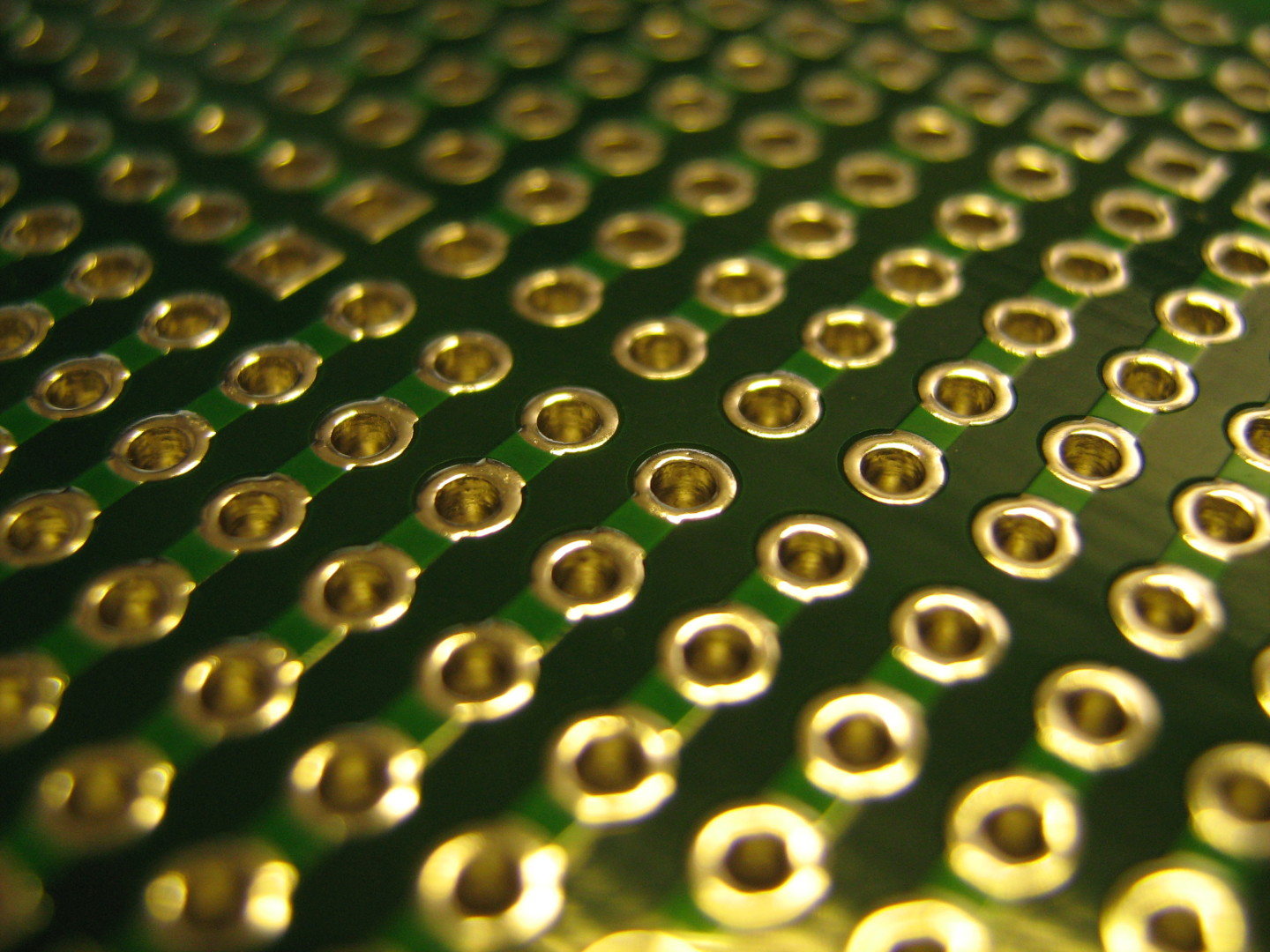

This board is the number 2 in the “Permanent Breadboards” series. This time, the layout is no more a simple direct copy of a classic breadboard: it’s a mix between a stripboard and an Arduino shield!

The Prototyping Boards are designed to offer the same look and feel as classic breadboards, with the ability to solder connexions: yes, you will have to solder 🙂

In other words, you’ll keep your prototype for life time!

Continue reading Prototyping Board 2: Arduino shield